Banner Slider

Blog post

The Role of Technology in Streamlining the Tax Recruiting Process

Technology in Streamlining the Tax Recruiting Process In today’s rapidly changing business landscape, it is important to capitalize on technology as a way to streamline operations and maximize efficiency. This is especially true for tax-related processes, as automation can help to minimize […]

Technology in Streamlining the Tax Recruiting Process

In today’s rapidly changing business landscape, it is important to capitalize on technology as a way to streamline operations and maximize efficiency. This is especially true for tax-related processes, as automation can help to minimize errors and ensure compliance with constantly evolving regulations. By integrating the latest technologies into their workflows, organizations can unleash significant savings and focus on strategic initiatives.

As a professional seeking new opportunities in the tax industry, working with a specialist recruiter can be an invaluable resource. A reputable recruitment agency will have a deep understanding of the skills, experience, and qualifications that are required for tax roles and will be able to align you with roles straight away, saving you time and effort by eliminating applications that are not a good fit. In addition, a specialist recruiter will also have access to a wide network of candidates and can tap into the latest job market trends, meaning that you will be able to find the right role more quickly.

Moreover, tax recruiting will have the expertise and resources to provide career guidance and advice to job seekers, helping them to navigate the interview process successfully. This is an extremely valuable service, as it can be difficult to sell yourself to a hiring manager without the right skills and training.

The Role of Technology in Streamlining the Tax Recruiting Process

In addition, tax recruiters will be able to advise on salary expectations and can provide information on the best markets to target when searching for a new role. This is particularly useful for job seekers looking to relocate, as it can be challenging to determine fair pay rates in unfamiliar regions.

As well as being able to offer guidance and support on the search for a new role, a reputable recruitment agency will also be able to provide advice and insight into the current state of the tax industry and the challenges facing it. This can be a great source of information for both job seekers and employers alike, as it will allow them to prepare themselves for future changes in the regulatory environment and take proactive steps to mitigate the risk of non-compliance.

One such example of this is the use of barcode technology to streamline tax disbursements processes. This technology allows businesses to scan receipts and invoices, automatically extract transaction details into the tax system, and submit documents in a single step. This eliminates the need for manual data entry and significantly reduces error rates. It also creates a reliable audit trail by linking physical documents to digital records. This makes it easier for auditors to trace transactions, verify accuracy, and identify discrepancies efficiently.

Other examples of tax-related technology include the use of Xero, an accounting software that integrates seamlessly with third-party apps to automate many manual tasks. This can save businesses a lot of time and resources, as it removes the need to manually transfer financial data between systems. It can also be used to manage a variety of other tax-related tasks, including automated bank reconciliation and customizable financial reports.

Related Posts

Printed Flexible Circuits and Smart Packaging

Printed Flexible Circuits The global market for smart packaging is expected to reach over 48 billion USD by 2024, and printed flexible circuits will have a huge role to play in this growth. Smart technology is being used by many companies to […]

Printed Flexible Circuits

The global market for smart packaging is expected to reach over 48 billion USD by 2024, and printed flexible circuits will have a huge role to play in this growth. Smart technology is being used by many companies to add functionality to their packaging that can improve customer experience and business outcomes. These functionalities can include tracking products during shipment, monitoring environmental conditions and even help authenticate real from counterfeit goods.

Printed flexible circuits (FFCs) are thin, flat, lightweight electronic components that replace the standard interconnection techniques such as soldered wires and hand-wired connectors. They are ideal for use in high-stress applications where the circuits will be subjected to continuous vibrations and mechanical stress. In addition, they offer better heat dissipation and electrical performance than rigid PCBs.

FFCs can be found in a wide variety of devices from mobile phones and tablets to computers and printers. They are also a critical component for smart packaging, as they allow for the integration of sensor technologies into the package itself. This allows for the creation of intelligent, connected packaging that can provide a more personalized customer experience and enhance product value.

A flex circuit is a printed electronic assembly made up of conductive traces on a flexible substrate with surface mount devices (SMD) attached to them. They are available in a range of sizes and thicknesses. The conductor layers can be made from a variety of materials, including copper foil. Depending on the application, they can be either single-sided or double-sided. Single-sided flex circuits consist of a single patterned conductor layer on a flexible dielectric film with termination features accessible only from one side.

Printed Flexible Circuits and Smart Packaging

These are the most commonly used type of flex circuits, and they are typically employed in IC packaging. Double-sided flex circuits contain a single conductor layer that is processed to allow access to the termination features from both sides. They are often employed in IC packages where tape automated bonding is employed.

In the case of smart packaging, a flex circuit can be embedded in the container or label and connects to sensors and actuators that monitor the condition of the packaged good. The data collected by the sensor can then be used to send a notification to a consumer or manufacturer, for example, if the package has been opened or tampered with.

As the COVID-19 pandemic changed consumer buying patterns, it was important for brands to establish a connection with their customers. For this reason, a number of retailers started using RFID to track inventory, which was especially useful for omnichannel retail models where consumers could order online and then pick up the items at a store location.

The use of RFID in smart packaging is only going to grow, as more and more businesses look for ways to add intelligence to their packaging at every stage of the supply chain. This is particularly true for healthcare companies, where flexible and printed electronics can be used to ensure the safety and quality of their products. For instance, Jones Healthcare Group has developed a system that can notify patients when it’s time to take their medication, via SMS text message or email.

Related Posts

How do flex PCBs accommodate for bending stresses?

flex PCBs accommodate for bending stresses The answer to how do flex PCBs accommodate for bending stresses is dependent on the overall thickness of the flex stackup and how rigid sections are configured. Thicker rigid flex PCBs tend to have more layers, […]

flex PCBs accommodate for bending stresses

The answer to how do flex PCBs accommodate for bending stresses is dependent on the overall thickness of the flex stackup and how rigid sections are configured. Thicker rigid flex PCBs tend to have more layers, which creates a larger amount of tensile stress. However, this is mitigated by the fact that rigid flex circuits usually have wider traces, which reduces stress concentration at bend points. In addition, the use of S curves in the flex region can reduce the chances of traces cracking and can also improve signal timing.

A flex pcb that is designed to be dynamic — one that undergoes repeated bending throughout its lifecycle — requires more rigorous design considerations than static designs. Typically, this includes having a minimum bending radius that is 100 times the thickness of the flex layer. This extensive bending radius is necessary to prevent the stress from concentrating on a single point, which can cause the flex to break.

Another way to improve the durability of a dynamic flex circuit is by using polyimide stiffeners. Stiffeners are additional layers added to the flex PCB that provide reinforcement in specific areas of the circuit. They are often used in areas where it is important to maintain rigidity, such as to protect components and connectors attached to the flex PCB. Stiffeners are available in a variety of thicknesses and can be made of either polyimide or metal (typically FR-4 or aluminum).

How do flex PCBs accommodate for bending stresses?

The material properties of the flex PCB should also be considered when designing for bending. For example, if the flex PCB will be exposed to harsh environments such as high temperatures, moisture, or vibration, it is critical that the correct materials are selected.

Finally, a dynamic flex circuit should be tested to ensure it is up to the task of handling repeated bending. This should include a thorough mechanical testing, such as physical bending of the flex PCB to its limits, along with electrical and environmental tests. The results of these tests can be used to refine the flex PCB’s design and ensure it meets all required specifications. This type of testing is crucial for ensuring that the flex PCB will perform reliably in its intended application.

In doing so, engineers can be confident that the flex PCB will meet the needs of its customers and perform well over time. This is why it’s essential to work with a fabricator that has experience producing quality flex circuits. PCBWay’s flex PCB assembly services are among the best in the industry and can help your design withstand repeated bending and other extreme conditions. Contact us today to learn more about our flex circuit assembly services. Our experienced team can help you design a functional and reliable product. We offer a wide variety of flex and rigid-flex circuit boards, including multilayer and double-sided flex PCBs, with a variety of finishes. We can also manufacture your flex circuits to your exact specification. We can even provide prototypes for your development process, so you can see and touch a sample of our work before ordering your production run.

Related Posts

Jerky of the Month Club – Recipes and Tips For Using Jerky

Jerky of the Month Club – Recipes and Tips For Using Jerky A curated monthly box of small-batch artisan jerky. Choose from 3, 6, and 12-month clubs with recurring or month-to-month payments and shipping to fit your lifestyle and budget. Jerky is […]

Jerky of the Month Club – Recipes and Tips For Using Jerky

A curated monthly box of small-batch artisan jerky. Choose from 3, 6, and 12-month clubs with recurring or month-to-month payments and shipping to fit your lifestyle and budget.

Jerky is more than a snack. It can be used in a variety of recipes to add flavor and protein! Try adding jerky to your favorite potato or macaroni salad.

Potato Salad or Macaroni Salad

Whether you’re looking for an easy, healthy snack or a tasty addition to the barbecue, potato salad or macaroni salad is a winner. This creamy side dish combines potatoes or macaroni pasta with vegetables, a tasty dressing and your choice of meat. It’s a great accompaniment to hamburgers and hot dogs on the grill or baked chicken, fried pork or smoked sausage for lunch.

Add a little jerky to the mix for an extra protein boost!

Our jerky of the month club offers 3, 6, or 12 month subscriptions to a rotating assortment of handcrafted beef jerky from top artisan jerky makers. The jerky is carefully curated so that you receive a delicious variety of flavors every month. Each shipment comes with large bags of jerky ranging in size from 7-8oz depending on the flavor. You can also add a personalized gift note to the package when you check out! This is the perfect gift for any jerky lover.

Macaroni and Cheese

For the mac and cheese lover, chop up your favorite jerky and sprinkle it on top of your homemade mac and cheese. It adds flavor and texture that is a lot healthier than using dried bacon bits.

Macaroni and cheese is a staple of American cuisine, and for good reason. It is a comfort food that is affordable to make, easy to ship and keep fresh and it fills up the belly. It has also been a popular snack for hikers and backpackers since the 1800s.

You can even make this dish a little bit healthier by using whole grain macaroni and milk, and substituting the Velveeta with a low fat version. Try adding different vegetables, beans or toppings to this cozy meal for variety. Make sure the jerky is thoroughly cooked before you add it to your mac and cheese. It is ready when it bends easily and the fibers are white. It will stay fresh for longer if you keep it in the refrigerator.

Chef or Garden Salad

Jerky is great for snacking, especially when you’re on the go. It provides a good dose of protein and it’s often a healthier option than other processed snacks.

You can make jerky at home using a modern dehydrator, a smoker or your oven. The drying process can take hours, but it’s worth the effort if you love beef jerky and want to save some money by making your own.

Start with a lean cut of meat, such as flank steak or round steak, which is the least expensive and is easily trimmed down to produce strips of beef jerky. You’ll also need some type of marinade and a dry rub to add flavor.

If you’re following a keto diet, jerky can be a great way to hit your fat and protein goals for the day. Try adding some jerky to a hard-boiled egg for a quick breakfast that packs a lot of punch. Or, try sauteing some jerky with veggies or beans in a pan for a satisfying dinner.

Potato Soup

There’s nothing cozier than a hearty bowl of potato soup. Adding jerky to this comforting meal makes it extra satisfying and delicious! Just make sure to use lean meat, as fat will spoil quicker when dehydrated.

The process of making jerky removes moisture and adds spices to help preserve it. This also brings it up to a high temperature, which kills any bacteria. It is important to cook your jerky to the right temperature, as it can be very dangerous to eat undercooked meat.

Jerky that is properly made can last a week at room temperature, a few months in the fridge and up to a year frozen. It’s best to always keep a stash in your pantry! If you’re looking to try new beef jerky flavors, consider signing up for a curated subscription box. You’ll receive an assortment of unique and delicious small-batch artisanal meats from around the country every month. Click here for more information!

Related Posts

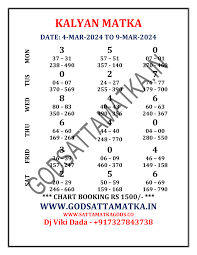

The Key Figures in the Development of Satta Matka

Development of Satta Matka Satta matka is a popular form of gambling in India that has evolved over the years to meet the needs of its players. The game has incorporated many modern methods while retaining its original essence, making it unique […]

Development of Satta Matka

Satta matka is a popular form of gambling in India that has evolved over the years to meet the needs of its players. The game has incorporated many modern methods while retaining its original essence, making it unique in the world of gambling. Its popularity reflects the aspirations and spirit of Indian people. Its enduring allure can be attributed to its ability to adapt to changing societal and economic conditions. Despite its allure, it is crucial for players to play responsibly and avoid becoming addicted to the game. Moreover, they should be aware of the legalities and risks involved in online gambling.

The evolution of satta matka can be attributed to the changing social and economic circumstances in India. Its popularity during the time of the textile mills was fueled by the need for an exciting pastime to relieve stress and monotony. Many mill workers were also keen on accumulating large amounts of money, which could be used to fulfill their financial goals and aspirations. The game soon gained traction in the city of Mumbai, where numerous textile mills were located.

During this period, the game was played by mill w, orkers and their families as a way to spend their free time. It was also an opportunity to earn big money in a short amount of time. In order to win, the players had to predict the opening and closing rates of various imaginary products. This was based on a random selection process of numbers or using a deck of playing cards. The winning number was declared at set times, which were called “sattas.” The sattas were drawn by a group of specialists called ‘matka kings’ or bookmakers. These bookmakers were able to predict the results of the satta and make large profits for their clients.

The Key Figures in the Development of Satta Matka

In the present day, satta matka has taken a more sophisticated approach to number selection. This has resulted in a greater element of skill and strategy, while still maintaining the excitement and unpredictability that has always been associated with the game. It has also been adapted to the convenience of users by being made available on various online platforms.

The development of satta matka is an ongoing journey, shaped by changes in society and the emergence of new technologies. A Satta matka development company must constantly innovate and keep up with the latest trends to remain competitive and stay relevant in the market. To achieve this goal, a satta matka development company must invest in research and development to develop innovative games that can attract the attention of players and boost its revenue.

A Satta Matka Development Company must also focus on building a strong brand image and reputation. This will help to establish the company as a leader in the industry and increase customer loyalty. It must also strive to deliver a high-quality product and provide excellent customer support to ensure that its games are as enjoyable as possible. This can be achieved by regularly updating its existing games to incorporate new features and content.

Related Posts

Can your wedding organizer Dubai accommodate last-minute requests?

wedding organizer Dubai accommodate last-minute requests The day of your wedding is one of the most memorable days of your life, and you want it to be perfect. A professional wedding planner in Dubai will make sure that all of your needs […]

wedding organizer Dubai accommodate last-minute requests

The day of your wedding is one of the most memorable days of your life, and you want it to be perfect. A professional wedding planner in Dubai will make sure that all of your needs are met and that the event runs smoothly. They will help you select vendors, create a budget, develop timelines, and ensure that the planning process is on schedule. They will also provide cost savings tips and a custom “to do” checklist that helps you stay organized.

Whether you’re planning a lavish affair or a more intimate celebration, a wedding organizer dubai will ensure that every detail is taken care of. These professionals have years of experience in creating dreamy, fairy-tale weddings for couples from all over the world. They understand the ins and outs of local laws, cultural nuances, and other factors that may affect your wedding.

A well-planned wedding is the foundation for a lifetime of happiness. However, it can be easy for the stress of planning to cloud your vision. That’s why it is important to trust your wedding planners and allow them to bring your vision to life. Having an open line of communication is vital, so be sure to share your dreams and expectations with your wedding planner Dubai.

Once you’ve found a Dubai wedding planner that meets your expectations, it is important to evaluate their credentials and expertise. Start by reviewing their portfolios and client reviews. This will give you a better understanding of their style and creativity. Also, pay attention to their level of experience in organizing destination weddings.

Can your wedding organizer Dubai accommodate last-minute requests?

Next, ask your potential wedding planners about their network of vendors in the region. A reputable company should have established relationships with reputable vendors that offer high-quality service at competitive rates. This will save you time and money in the long run. Lastly, ask about their legal and cultural knowledge of the UAE. This will help you avoid unforeseen expenses and minimize the risk of any last-minute surprises.

A good wedding planner will work within your budget to create a truly memorable occasion. They will take the time to listen to your ideas and incorporate them into the final design, all while staying true to the overall theme of your wedding. Moreover, they will communicate openly about your financial constraints and work diligently to maximize the impact of each dollar spent.

Communication is key when working with a wedding organizer, so be sure to choose someone with whom you feel comfortable and confident. Schedule initial consultations with potential candidates to discuss your vision for the wedding and assess their professionalism and responsiveness. Trust your instincts and choose a wedding organizer who listens to your ideas and understands your vision for the big day.

In conclusion, hiring a wedding organizer in Dubai is essential for couples seeking a seamless and stress-free planning experience. From venue selection to vendor coordination, their expertise and local knowledge ensure that every aspect of your wedding is executed flawlessly. By choosing the right wedding organizer, you can relax and enjoy the journey to your happily ever after in the dazzling city of Dubai.

How Do I Ask For Severance Pay When Resigning?

Severance Pay When Resigning As an employee, you probably have many concerns and details on your mind when it comes to a possible job transition. Some of the most common are how you will find a new position and make ends meet […]

Severance Pay When Resigning

As an employee, you probably have many concerns and details on your mind when it comes to a possible job transition. Some of the most common are how you will find a new position and make ends meet during the bridge period between careers. One option some companies offer to help ease the transition is severance pay.

Severance pay is money an employer gives you upon your termination, usually in exchange for signing a release of any claims against the company. The amount is usually based on the number of years you’ve worked and the salary you’ve earned in that time frame. Middle managers and executives typically receive a higher amount than entry-level employees.

When a company announces mass layoffs, severance pay is often offered to help those who are losing their jobs. The company may also offer severance pay if you’re being terminated without cause or if the job requirements were changed and it no longer made sense for you to continue working there.

Companies are not required to provide severance pay to workers, but they often do because it helps ease the transition for those who lose their employment and helps to keep positive word-of-mouth about the company during a tough time. Some employers even offer severance packages to employees who are resigning voluntarily so they don’t feel left out in the cold.

How Do I Ask For Severance Pay When Resigning?

If you’re being laid off, you may be able to negotiate a higher severance package if you can demonstrate that you were told certain things when you signed your contract that were not true and could be considered misleading. This is not a situation that you should try to handle on your own. You should seek out an experienced employment law attorney to assist you.

It’s important to think about the tax implications of any define severance pay you might receive. Depending on how your employer pays the money, it may be taxable as regular wages or as supplemental income. You can ask your employer to pay it in installments over two years if necessary to avoid paying too much in taxes. You should also determine if your employer will continue to pay for your health insurance, compensation for any unused vacation and sick time, or perks like company-sponsored discounts or equipment.

Moreover, severance pay acknowledges the contributions and service of departing employees to the organization. It reflects a degree of respect and appreciation for their dedication and commitment, helping to soften the emotional blow of job loss. This recognition can foster goodwill between the employer and the departing employee, mitigating potential resentment and facilitating a smoother departure process.

From an employer’s perspective, offering severance pay can be seen as a strategic investment in maintaining a positive employer brand and reputation. How a company treats its departing employees can significantly impact its attractiveness to both current and prospective staff. Generous severance packages demonstrate a commitment to employee well-being and can enhance employer credibility, potentially leading to better retention rates and a more engaged workforce in the long run.

Can I Find Refurbished Laptops With High-Resolution Displays?

Refurbished Laptops With High-Resolution Displays When searching for the perfect laptop computer, a high-resolution display is one of the most important features to consider. This will ensure that you are able to see all of the fine details on your screen, whether […]

Refurbished Laptops With High-Resolution Displays

When searching for the perfect laptop computer, a high-resolution display is one of the most important features to consider. This will ensure that you are able to see all of the fine details on your screen, whether you are working or just enjoying entertainment.

While some may be hesitant to purchase a used or previously owned laptop, refurbished computers have many benefits. They are often priced lower than new computers, and they are inspected, cleaned, and repaired by professionals before being sold again. Many of the top refurbished laptops on the market feature high-resolution displays, making them ideal for business users or those who need to get work done on the go.

In general, a refurbished laptop will have less advanced components than a brand-new laptop, but this is not always the case. It is important to use a hardware comparison website to compare the specifications of a new laptop with a refurbished laptop that has the same specification to ensure you are getting the best value for your money.

Can I Find Refurbished Laptops With High-Resolution Displays?

Buying a refurbished laptop can also save you a significant amount of money, as you will not be paying for any additional components that are not necessary for your use. Additionally, you will be reducing your impact on the environment by ensuring that perfectly good laptops are not being thrown away. If you are looking for a great deal on a quality refurbished laptop, look no further than Micro Centers lineup of options.

Most refurbished laptops sold today are going to have at least a 1080p FHD IPS screen with fairly decent color reproduction. This resolution is standard, and most laptops have been shipping with these displays for quite some time now. However, some laptops are still shipped with lower quality 1366 x 768 TN screens in order to cut costs for business models.

When shopping for a refurbished laptop, it is important to know who the laptop was sourced from and what refurbishing process was utilized. This is because not all refurbishing processes are created equal. Ideally, the laptop should be restored to a condition that is similar to when it was originally built. In addition, the laptop should have a clean exterior with no cosmetic blemishes.

If you’re a student, a refurbished laptop is a great way to make your money stretch further. These laptops are typically tested for defects, and they come with a warranty that covers any problems that might arise. You can even find a high-resolution refurbished laptop for under $500, which is a great price to pay for an affordable laptop that will meet your needs. The only downside to purchasing a refurbished laptop is that you might be locked out of future OS updates, which is something that you should weigh with your specific use cases in mind. If you are a fan of Apple products, for example, you should be aware that macOS updates will stop supporting older MacBooks after seven years.

Related Posts

Greece Yacht Hire – The Ultimate Sailing Vacation

Greece Yacht Hire With over 6,000 islands and islets, Greece yacht hire is a must for any sailing enthusiast. It’s a timeless land of dazzling white sand beaches, crystal clear anchorages, towering limestone cliffs, and quiet villages where brightly painted fishing boats […]

Greece Yacht Hire

With over 6,000 islands and islets, Greece yacht hire is a must for any sailing enthusiast. It’s a timeless land of dazzling white sand beaches, crystal clear anchorages, towering limestone cliffs, and quiet villages where brightly painted fishing boats bob in pretty harbours. Then there are the island party hubs of Mykonos and Santorini, where you can dance the night away with an international crowd of sun bronzed lovers until the early hours.

With a vast choice of charter types available, finding the perfect yacht to match your group’s size and experience level is easy. Motorboats are the most popular, but you can also rent a catamaran or a traditional sail boat for a more authentic sailing experience. Some of the top brands include Beneteau, Jeanneau, Fountaine Pajot, Bavaria, Lagoon, and more. The best time of year for a yacht vacation in Greece is from May to the end of October. The meltemi wind is typically calmer at this time, so you can explore the waters without feeling like you’re being buffeted around.

Sailing with a skipper means you can relax and enjoy the beauty of Greece’s spectacular islands. This option is perfect for those with limited time who want a stress-free vacation. Skippers are highly trained to provide the most enjoyable and safest sailing experience possible. Plus, they’re knowledgeable about the area and will help you discover the most beautiful spots to visit on your Greece yacht hire.

Greece Yacht Hire – The Ultimate Sailing Vacation

For those who would prefer to let someone else take the reins, there are plenty of crewed yachts to choose from as well. These vessels come with a professional captain and full crew who will make your trip a memorable one. They can arrange your itinerary, prepare delicious meals, and even organize excursions to the islands you’ll be visiting.

Bareboat yachts are also a great option for those with a valid RYA International Certificate of Competence (ICC). However, it’s important to note that bareboats must have a co-skipper with a license or they will be assigned a local skipper for a fee. The cost of the charter can also vary depending on the length of the trip and season for more information click here.

To get the most out of your yacht rental in Greece, we recommend planning a weeklong adventure. This will give you enough time to enjoy all the beautiful beaches, quaint villages, and bustling party scenes that Greece has to offer.

To start your sailing vacation in style, book a boat with Click&Boat. Our simple booking process makes it quick and easy to find and book the ideal boat for your dream cruise. Plus, our flexible cancellation policy allows you to change your plans up to 15 days before check-in. So book your luxury yacht in Greece today and create a once-in-a-lifetime sailing vacation! You won’t regret it.

Related Posts

Is hair dryer diffuser good for hair?

hair dryer diffuser When you open your brand new hair dryer, there’s a little something extra in the box: A diffuser. The circular, pokey attachment is a new must-have for curly and wavy ladies looking to achieve beach-goddess curls and waves. While […]

hair dryer diffuser

When you open your brand new hair dryer, there’s a little something extra in the box: A diffuser. The circular, pokey attachment is a new must-have for curly and wavy ladies looking to achieve beach-goddess curls and waves. While it may seem like a confusing add-on, using one is actually a breeze once you know how to do it right.

Diffusers soften the harsh blast of heat from your usual hair dryer with diffuser, making them better for delicate strands and perfecting scrunching techniques that encourage curls. Plus, they distribute air evenly throughout your strands, so you can dry your entire mane without worrying about overheating certain areas (read: frizz). So if you’re thinking of trying out a diffuser for the first time or want to learn how to use your new tool, read on for quick tips, a guide on how to use a hair dryer with a diffuser, and the best diffusers on the market today.

The first step in ensuring you’re getting the most out of your diffuser is to start with clean, damp hair that’s been spritzed liberally with your favorite heat protectant spray. Then, attach your diffuser and make sure it’s locked in — “it can be easy to accidentally bump a diffuser off while blow-drying your hair and ruin the shape you’re working so hard for,” stylist Nika Torres tells SELF.

Is hair dryer diffuser good for hair?

Once you’re ready to start, you can begin diffusing in sections. “Take a handful of your curls and coil them in the diffuser, letting them drop down and away from the head,” Torres says. “Don’t push down or bunch them up; this can disturb the clumps and curl pattern you’re working so hard to create.” Then, move on to the next section and continue to do so until your whole head is about 80% dry.

While you’re drying your hair, avoid touching it or twirling it around—doing so can disrupt the curl pattern and lead to frizz and flyaways. “You’ll also want to avoid combing it with a brush or comb, which can cause frizz,” Torres says. Instead, opt for a wide-tooth comb to detangle your strands.

Unlike other traditional plastic options, this foam-sock diffuser collapses flat for easy storage, making it easier to fit into your bag when traveling. It’s also incredibly lightweight so it won’t turn your normal blow-drying routine into an arm workout. Plus, it’s a great option for dry summer months when humidity can make hair extra frizzy. The best part: It’s super affordable, too. So whether you’re on a budget or just looking for a good deal, this diffuser is worth considering. (It’s available in a variety of colors, too.) It has a 4.4-star rating from more than 2,000 Amazon reviewers, and it should easily clip onto any hair dryer nozzle. Plus, it’s easy to clean and comes with a convenient carrying pouch.